No Saw Cuts, No Dominant Joints

Jointless As Far As The Eye Can See

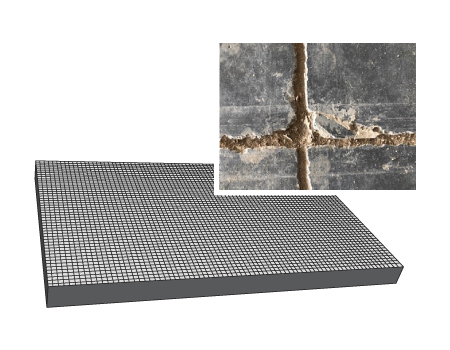

Owners have options when choosing the industrial flooring for their warehouses, distribution centers, and other commercial properties. Traditional concrete has been used for hundreds of years and is known: expectations of maintenance, deterioration at the miles of saw cuts and joints, and ongoing repairs are assumed and accepted.

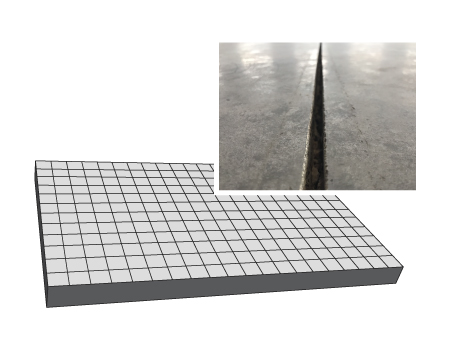

In recent years, however, “extended joint” systems have offered an alternative, providing industrial flooring with fewer miles of saw cuts and joints to maintain. There are several of these options, which are often available at a far greater cost than traditional concrete. While reducing the joints, these systems often have wide “Dominant Joints: between panels that often open 3/8” or wider.

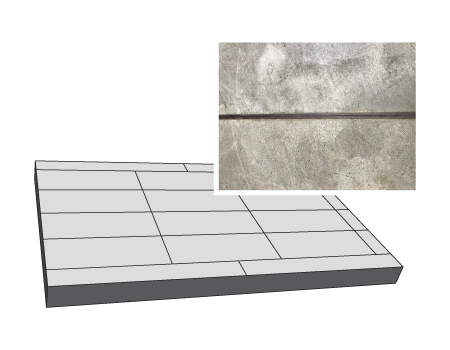

PrimX goes beyond the “extended” options, by removing ALL saw cuts and providing tight construction joints between daily pours. In the example shown below, the PrimX alternate reduced the lineal feet of joints to less than one mile from 18 Miles with traditional concrete.

Distribution Center Example

615,780 sf

Traditional Concrete

96,000 Lineal Feet

(18 Miles)

of Saw Cuts & Construction Joints

Extended Joint

24,500 Lineal Feet

(4.6 Miles)

of Dominant Joints (3/8″ joints)

PrīmX Joint

3,500 Lineal Feet

(.6 Miles)

of Tight Construction Joints